MULTI TECH ENGINEERING Gyro screens

MultiTech Engineering Gyro screens is planned to increase the efficiency of your screening

process while simultaneously reducing power consumption. This advanced Gyro screen

ensures optimal results across various materials—wet, dry, coarse, fine, hot, or cold.

THE ROBUST

HIGH

VIBRATION SIEVE

Product Enquiry

Working

Principle

PROVIDES TWO-TIMES HEIGHER VIBRATIONS

It is suitable for Dry or Wet Applications like Silica, Ceramics, Powder paint, Tapioca starch, Coffee beans, Copper powder, Silver powder, & lot more. MultiTech Vibrating sieve machine comes with a variant in sizes to cater to the need of different industries like, Food & Beverages, Pharmaceutical, Paper& Pulp, Metals industry and many more.

PRODUCT

Feature

01. Compact Design which is easily incorporated into processing line

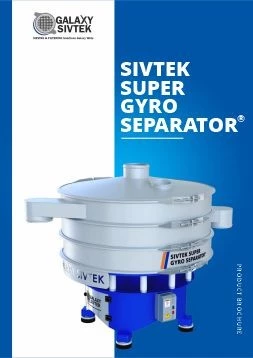

The Super Gyratory Separator has a compact design that provides low headroom and can be easily incorporated into the processing line.

02. Adjustable Lead Angle to control the fineness according to your screening requirements.

The gyratory separator has adjustable lead angles which allows you to control the fineness according to your screening requirements.

03.Very Navigable due to its compact body accompanied by the castor wheels

The compact body of the Super Gyratory Separator, accompanied by the castor wheels, is highly mobile and easy to maneuver.

PRODUCT

Advantage

01. Higher number of Vibrations as compared to conventional Gyro Screen.

The eccentric weights on the upper and lower ends of the motion generator shaft allow the separator to produce twice the amount of vibration in comparison to other gyratory separators.

02. Higher Output

Because of the centerline inlet and outlet design, the inline sifter reduces the movement of screening material and provides higher output compared to conventional machines.

03. Requires lesser manpower

The Super Gyratory Separator is highly maneuverable due to the castor wheels which reduces the number of hands required for its operation.

04. Highly navigable due to castor wheels

The Super Gyratory Separator is highly maneuverable due to the castor wheels which reduces the number of hands required for its operation.

Frequently

Asked Questions

For what kind of applications Multi Tech Engineering Gyro screens can be used?

Up to what mesh size Gyro screens can sieve?

How is the material being fed in the centre at different levels of machines?

Difference between Multi tech Engineering gyro screens and Multi Tech Engineering Vibro screens.

What kind of motors are provided by the Multi Tech engineering?

Valued

Resources

Product Brochure

Product Brochure

Product Brochure