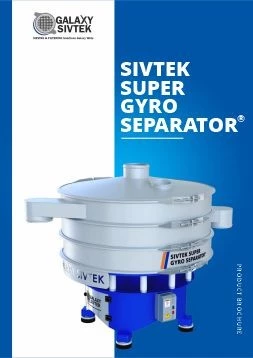

TECH ENGINEERING SUPER GYRO SEPARATOR®

THE ROBUST

HIGH

VIBRATION SIEVE

Product Enquiry

Working

Principle

PROVIDES TWO-TIMES HEIGHER VIBRATIONS

Our Super gyratory screener® can produce such high-intensity vibrations due to its eccentric weights on the upper and lower ends of the motion generator shaft. While the top weight distributes the material across the screen, the lower weight tilts the machine to generate vertical vibrations.

PRODUCT

Feature

01. Vertical + Horizontal Vibrations to maximize the flow through of the material.

The Super Gyratory Separator has a compact design that provides low headroom and can be easily incorporated into the processing line.

02. Centerline inlet and outlet reduce screening material movement thereby reducing screening time.

The gyratory separator has adjustable lead angles which allows you to control the fineness according to your screening requirements.

PRODUCT

Advantage

01. Higher Output

The eccentric weights on the upper and lower ends of the motion generator shaft allow the separator to produce twice the amount of vibration in comparison to other gyratory separators.

02.Generates Higher Vibration through two motors attached

Because of the centerline inlet and outlet design, the inline sifter reduces the movement of screening material and provides higher output compared to conventional machines.

03. Requires lesser manpower

The Super Gyratory Separator is highly maneuverable due to the castor wheels which reduces the number of hands required for its operation.

Frequently

Asked Questions

What is the maximum height of the low-profile separator?

What is the working principle of the 3600 discharge separator?

What kind of motors are provided by Multi Tech Engineering?

What are the various certifications available with the machine?

What are the customizations available?

Can this machine be used for dry and wet applications?

Valued

Resources

Product Brochure

Product Brochure

Product Brochure