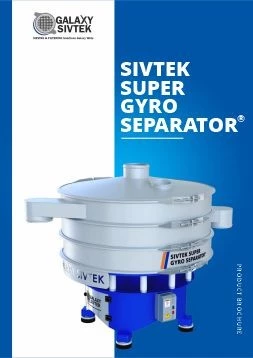

TECH ENGINEERING VIBRO SEPARATOR®

It is a highly efficient sieve separator machine that offers maximum capacity in your current

processing line targeted to give best performance for the production to reach its desired level

of output.

THE ROBUST

HIGH

VIBRATION SIEVE

Product Enquiry

Working

Principle

PROVIDES TWO-TIMES HEIGHER VIBRATIONS

Our Super gyratory screener® can produce such high-intensity vibrations due to its eccentric weights on the upper and lower ends of the motion generator shaft. While the top weight distributes the material across the screen, the lower weight tilts the machine to generate vertical vibrations.

PRODUCT

Feature

01. Noise Level below 75DB

The Super Gyratory Separator has a compact design that provides low headroom and can be easily incorporated into the processing line.

02. Dust-Tight for 0% contamination

The gyratory separator has adjustable lead angles which allows you to control the fineness according to your screening requirements.

PRODUCT

Advantage

01. Noise Controlled Processing

The eccentric weights on the upper and lower ends of the motion generator shaft allow the separator to produce twice the amount of vibration in comparison to other gyratory separators.

02. Cost Efficient

Because of the centerline inlet and outlet design, the inline sifter reduces the movement of screening material and provides higher output compared to conventional machines.

03. Reduced Cleaning Time

The Super Gyratory Separator is highly maneuverable due to the castor wheels which reduces the number of hands required for its operation.

Frequently

Asked Questions

What kind of applications can the Multi Tech Vibro Separator be used?

What kind of materials can be sieved with the help of Multi Tech Vibro Separator?

It is suitable for both dry and wet applications, the Sivtek Super Gyro Separator® can be used in food industry, pharmaceutical industry, mineral and metals industry, plastic, pigment industry, etc.

What are the solutions provided for the unclogging of the mesh ?

The Sivtek Super Gyro Separator® can sieve from 10mm to 25 Micron screen or 500µ, easily for a range of materials having higher to lower bulk density. This gives us a wider range of applications to cater and provide solutions. These meshes are FDA and cGMP compliant to maintain the hygienic and quality standards.

Steps taken to remove the ferrous contaminants.

What are the different customizations available for the Multi Tech Vibro Separator ?

The Tech Engineering Super Gyro Separator® can generate Two times more vibrations than a Sivtek Vibro Separator®, which can deliver higher throughput and increased efficiency with ultra-fine mesh as compared to the same size gyratory separator.

What is the mesh size up to which the Mu;ti Tech Vibro Separator can sieve ?

Valued

Resources

Product Brochure

Product Brochure

Product Brochure