ACCESSORIES.

Clean in place System

DEBLIND

YOUR

MESH

They don’t only help you increase your efficiency and productivity, but they also help you to keep the screens clean and increase their lifespan. Furthermore, they also reduce wastage which adds to cost cutting.

Working

Principle

Clean in place systems for sifters and filters

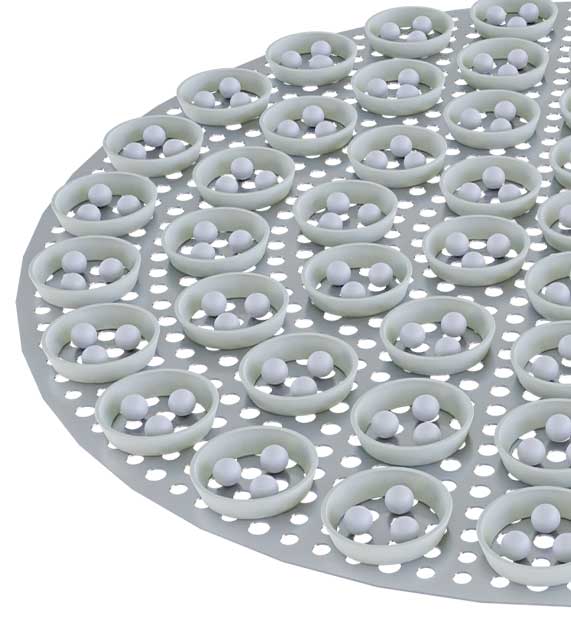

Mesh Deblinding Kit (MDK) is an anti-blinding ball tray arrangements which is installed underneath the sizing mesh. On that ball tray, enough elastomer or polymer balls are arranged that constantly tap the sizing screen. As the balls keep tapping the screen, all the dry screening particles that are clogged in and around the screen are released and help you increase your screening efficiency.

PRODUCT

features

TECHNICAL

Specifications

- Suitable for all the round vibro separators from 18” to 84”.

The range of nozzles come from 2 to 12 depending upon the diameter of the machine.

The CIP system comes with manual as well as PLC operated system which runs automatically after every batch or whenever programmed.